Expert CNC Services Across the Midlands

Factories across the Midlands trust us to keep their CNC equipment in peak condition, whether they're facing an unexpected breakdown or planning for future productivity. From urgent call-outs to precision calibration and rebuilds, our team is dedicated to getting your operations back on track, quickly and right first time.

With decades of expertise and a reputation for specialist machine tool repairs, Matrix is the CNC partner for manufacturing businesses across Coventry, Manchester, Sheffield, Bristol, Cardiff, and throughout the Midlands.

Industries We Operate In

Matrix CNC is proud to support manufacturing and engineering sectors across Coventry, Sheffield, Manchester, Swindon, Peterborough, Cardiff, and the wider Midlands area, providing reliable CNC machine repairs.

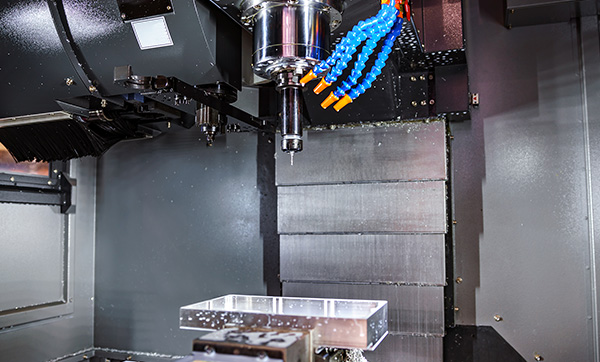

General Manufacturing

Repairs and maintenance for high‑output factories of all sizes.

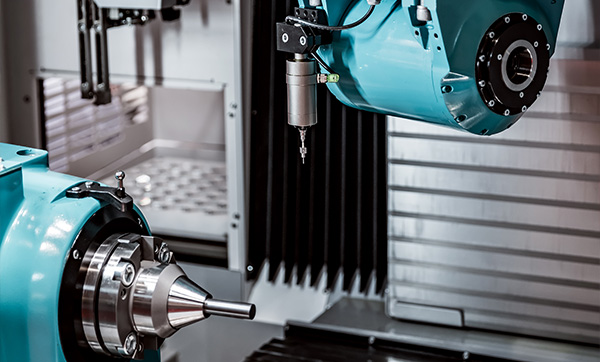

Precision Engineering

CNC calibration and geometry for accurate, repeatable production.

Toolmaking

Machine installations and rebuilds for demanding toolroom environments.

Medical Device Production

Ensuring compliance and reliability for regulated sectors.

Oil and Gas

Breakdown repairs and upgrades for robust, heavy-duty applications.

Automotive & Aerospace

Servicing mission critical machine tools and controls for precision parts and assemblies.

We understand each sector's specialised challenges and bring the knowledge and dedication needed to solve them.

Frequently Asked Questions

How to diagnose a CNC fault?

We diagnose CNC faults on-site using advanced tools to assess spindle motors, drives, wiring, and control panels. Our experts quickly identify electrical or mechanical issues across most brands, including Fanuc, Siemens, and Heidenhain.

Do you offer remote CNC diagnostics?

Yes, we provide a remote diagnostic service for certain fault types. We guide on-site teams through initial troubleshooting to support rapid fault resolution and minimise machine downtime.

How quickly can you respond to a breakdown?

We prioritise urgent CNC breakdown repairs and typically offer same or next-day response across the Midlands, including Manchester, Sheffield, Bristol, and Cardiff.

Do you work with all CNC control systems?

We specialise in Fanuc, Siemens, and Heidenhain control systems but support most CNC brands and models with both electrical and mechanical repairs.

What areas do you cover?

Matrix CNC serves the Midlands region from Coventry, extending north to Manchester and Sheffield, and south towards Bristol, Cardiff, Peterborough, and Swindon.

What’s the benefit of a service contract vs ad hoc repair?

A CNC service contract provides scheduled maintenance, early fault detection, reduced breakdown risk, and higher machine reliability, while ad hoc repairs address issues only when they arise.

Do you offer support for older machines?

Absolutely. We offer machine rebuilding, refurbishments, and upgrades—modernising control systems and mechanical elements for older CNC machines to extend their service life.

Keep Your CNC Machines Running with Fast, Expert Support

Enquire about our specialist CNC machine services—fast, reliable and expert support is just a click away. Contact us now on 07856 977419 or 07904 912022, or email service@matrix-cnc.co.uk to keep your operations running smoothly.

Navigation

Matrix CNC is registered as a limited company in England and Wales under company number 15407485.