CNC Machine Geometry Checking and Calibration

Our geometry checks and calibrations are designed to help you meet demanding tolerances and maintain consistent part quality.

At Matrix CNC, our experienced engineers provide:

Accurate machine alignment and recalibration for all brands and models.

Precision CNC testing using laser and dial-based instruments.

Detailed axis straightness, squareness, and backlash adjustments.

Reliable post-installation validation for new or relocated equipment.

Full-service mechanical and electrical CNC engineering.

Support for Fanuc, Heidenhain, Siemens and multi-axis CNC machine types.

Quick response times across The Midlands to minimise downtime.

Thorough CNC machine repair diagnostics and fault finding, including remote CNC diagnostics.

With Matrix CNC, you can expect industrial reliability and service designed to ensure your machines deliver repeatable results shift after shift.

How We Help Your Operations

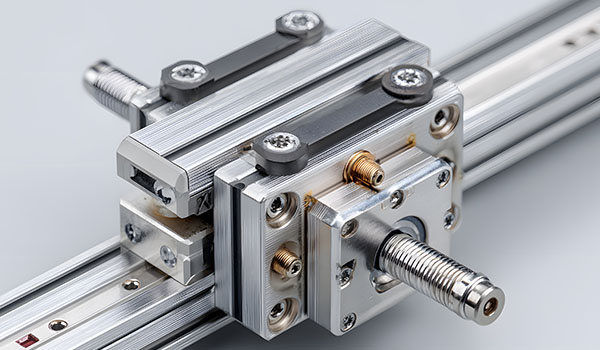

Machine Alignment and Recalibration

When a CNC machine slowly shifts out of alignment, productivity and product quality suffer. Our CNC testing and alignment services re-centre your equipment to its original tolerances.

Matrix CNC engineers use both dial and laser tools to check critical reference points and return your machines to peak accuracy. This minimises wear and tear, boosts repeatability, and helps you achieve higher precision with every job.

Axis Straightness, Squareness, and Backlash Adjustment

Tiny movements in axis straightness or squareness can mean big losses in manufacturing accuracy. We meticulously verify each axis, making targeted mechanical adjustments to correct errors and balance backlash. By restoring straightness and squareness, Matrix CNC ensures every component produced on your machine meets the strictest quality requirements.

Our adjustments are informed by decades of experience, helping you avoid repeat faults and unnecessary repair costs.

Laser or Dial-Based Geometry Testing

Our engineers use industry-leading laser and dial test methods tailored to your machine. Laser tools offer unparalleled precision for checking alignment over long travels, while dial indicators are ideal for verifying smaller components and assemblies.

Detailed geometry reports provide you with clear evidence of your equipment's condition and any corrective work needed. These tests form the foundation of ongoing, reliable operations for industrial CNC users across The Midlands.

Post-Installation Validation

After installing new machinery or relocating existing equipment, post-installation validation is essential. Matrix CNC conducts thorough validation checks to ensure every system is level, square, and operating at optimal performance before production restarts.

This gives our customers confidence that their investments are protected and that any issues are resolved promptly.

By choosing Matrix CNC for geometry checks and mechanical adjustments, you gain a partner who understands the demands of high-precision manufacturing. Our multi-brand expertise means we can work with Doosan, Fanuc, Heidenhain, Siemens and many more brands, providing tailored recommendations for your workshop. Regular CNC testing protects your equipment, keeping your factory productive and your customers satisfied.

Frequently Asked Questions

How do you test for CNC accuracy?

We test CNC accuracy using laser and dial-based instruments to check alignment, axis straightness, squareness, and backlash, ensuring machines operate to precise tolerances.

What are CNC geometry checks?

CNC geometry checks involve assessing and restoring the correct alignment, straightness, and squareness of a machine’s moving parts to maintain accuracy and repeatability.

Why are regular CNC geometry checks important?

Regular geometry checks safeguard your CNC machine’s performance and productivity, preventing errors, preserving accuracy, and minimising unplanned downtime.

What mechanical adjustments do Matrix CNC offer in the Midlands?

Matrix CNC provides machine alignment, axis squareness and backlash adjustment, laser/dial-based geometry testing, and post-installation validation across the Midlands.

Can Matrix CNC calibrate multi-axis CNC machines?

Yes, we specialise in multi-axis CNC machine calibration, supporting controls such as Fanuc, Heidenhain, Siemens, and others for optimum industrial accuracy.

How quickly can you respond to a CNC geometry fault in the Midlands?

We offer fast response times across the Midlands, prioritising urgent CNC machine repair and geometry checks to reduce your downtime.

Want Greater CNC Precision and Reliability?

Don't risk poor part quality or unexpected downtime. Contact Matrix CNC for accurate CNC repair, testing, geometry checks, and mechanical adjustments in The Midlands.

Our experienced team is ready to keep your operation performing at its best. Call 07856 977419 or 07904 912022, or email service@matrix-cnc.co.uk for a fast, reliable response.

Navigation

Matrix CNC is registered as a limited company in England and Wales under company number 15407485.