CNC Machine Performance and Accuracy Testing – What We Offer

When you choose Matrix CNC for your CNC refurbishment in the Midlands, you benefit from a complete, expert-led service that covers every aspect of machine rebuilding and refurbishing. Our process includes:

Complete machine disassembly and thorough inspection

We carefully dismantle the machine and inspect each part for wear or damage, ensuring nothing is missed.

Component rebuilding, repair or replacement

Worn components are rebuilt when possible or replaced using new or expertly re-machined parts.

Precision resurfacing and alignment

We restore worn surfaces, scrape and sand them, and realign the machine to original specifications for improved accuracy.

Replacement of seals and full lubrication

New seals are installed, and all components are lubricated for smooth, long-term operation.

Functional and accuracy testing

Every CNC refurbishment is tested rigorously, confirming it meets all performance specifications before recommissioning.

Specialist Turcite repair and restoring Turcite material

We are experienced in restoring critical Turcite surfaces to maintain precision and reliability.

How We Help Your Operations – Machine Rebuilding and Refurbishment Services

At Matrix CNC, our CNC refurbishment services in the Midlands are designed to support manufacturers who demand reliability and accuracy. Our services include:

Full or Partial Rebuilds

We can completely strip down your CNC machine, analyse every component, and rebuild the assembly from the ground up, or focus on specific worn areas. Whether your requirement is a partial intervention or a full machine overhaul, Matrix CNC has the knowledge to keep your production consistent.

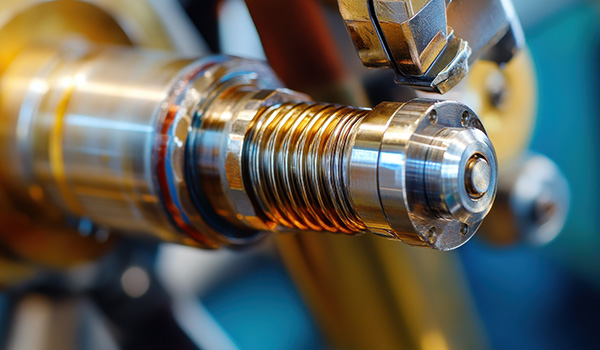

Ball Screw Replacement and Slideway Regrinding

Precision is everything for CNC machinery. We offer accurate ball screw replacement and expert slideway regrinding to eliminate backlash and ensure smooth, repeatable movement. If your guideways or screws show wear, our regrinding and replacement services restore original tolerances for optimal machine performance.

Electrical Cabinet and Control System Refresh

Over time, control electronics and wiring can degrade or become obsolete. Our team refreshes control systems and electrical cabinets to reduce downtime and avoid unexpected failures. This service is crucial for manufacturers using Fanuc, Heidenhain or Siemens controls, and ensures continued reliability from your CNC equipment.

Upgrade Older Machines for

New Production Requirements

Don't let older CNC machinery limit your business. We upgrade legacy equipment to meet new production demands, including interfacing, add-ons, and improved automation. This approach provides an affordable alternative to full machine replacement, letting you future-proof your investment and maintain productivity.

CNC Machine Repair and Emergency Support

Matrix CNC provides fast, affordable CNC machine repair for breakdowns across the Midlands. Our responsive team is on hand when you need urgent repairs or expert advice, helping minimise your factory's downtime and maximise profitability.

No matter your sector – from Coventry to Manchester, Sheffield to Cardiff – our reputation for thorough, right-first-time CNC refurbishment is why manufacturers trust Matrix CNC throughout the region.

Frequently Asked Questions

How do I repair or refurbish a CNC machine?

A proper CNC refurbishment involves full disassembly, inspection, replacing or rebuilding worn components, resurfacing, realignment, lubrication, and comprehensive functional testing.

Where can I get fast CNC machine repairs in the Midlands?

Matrix CNC offers fast CNC machine repair and refurbishment services across the Midlands, minimising factory downtime and restoring full machine function promptly.

How is Turcite restored during CNC refurbishment?

Restoring Turcite involves replacing or repairing worn Turcite surfaces to regain original precision and reduce friction, improving machine accuracy and lifespan.

What CNC refurbishment services does Matrix CNC provide?

Matrix CNC provides full or partial rebuilds, ball screw replacement, slideway regrinding, electrical system refresh, control upgrades, and emergency CNC repair.

How does CNC machine rebuilding benefit manufacturers?

CNC rebuilding restores lost accuracy, extends lifespan, boosts production reliability, and upgrades older machines to meet new production requirements cost-effectively.

Do you handle all CNC control brands for refurbishment?

Yes, Matrix CNC is experienced with Fanuc, Heidenhain, and Siemens systems, offering refurbishment and repair across all major CNC control brands.

Get Your CNC Back to Full Performance

Don't wait for a breakdown to impact your bottom line. Call us on 07856 977419 or 07904 912022, or email service@matrix-cnc.co.uk for expert CNC refurbishment in the Midlands.

Navigation

Matrix CNC is registered as a limited company in England and Wales under company number 15407485.